2025/10/10

ANA's airplanes are equipped with various items that make customers' sky journeys comfortable, including seat covers.

However, due to equipment updates and maintenance, many seat covers that are still in good condition get discarded.

To give new life to these valuable resources by turning them into products with renewed value, we launched the ANA Upcycle Project.

Creating High Quality Products through Joint Development with Onward

This project was not simply about recycling waste, but about delivering high quality, well-designed products that customers would truly value.

To make this possible, ANA partnered with an apparel manufacturer renowned for its advanced technology—Onward Corporate Design Co., Ltd. (formerly Onward Trading Co., Ltd.; hereafter "Onward").

Onward's Re-make-up Project involves using its technology to upcycle discarded clothing, and it shares the same aspiration as the ANA Group's ANA Future Promise initiative to reduce environmental impact.

The alignment of both companies' philosophies made us confident that we could go beyond mere product manufacturing to create works of great value.

As a result, the first line of upcycled products was created in 2022—the ANA Original Room Shoes, born from seat covers that had completed their journeys in the sky.

Second Upcycled Product: ANA Original Patchwork Cushion

The first upcycled product was well received, but its production process left behind many fabric offcuts.

We hoped to make the most of these valuable resources, including even the smallest pieces. This led to the creation of our second upcycled product—the ANA Original Patchwork Cushion.

This cushion features a one-of-a-kind design created by combining five patterns of ANA airplane seat covers.*

The patchwork process requires fabric pieces with different thicknesses and textures to be carefully stitched by hand. It is only possible through the skill of experienced craftworkers and meticulous attention to detail.

The process ranges from carefully cutting out fabric pieces at a factory in Yamagata Prefecture to sewing and inspecting at a workshop in Hyogo Prefecture. The resulting cushions embody the dedication of the many people involved.

The cushion's lining also reuses curtains once used in airplane galleys.

Thanks to these efforts, about 85% of discarded seat covers have been successfully upcycled.

- * The five seat cover patterns come from the following: B767 / B787 domestic economy class, B737 domestic economy class, Q400 domestic economy class, A320 / A321 premium business class, and B787 premium business class.

Comment from a Project Member

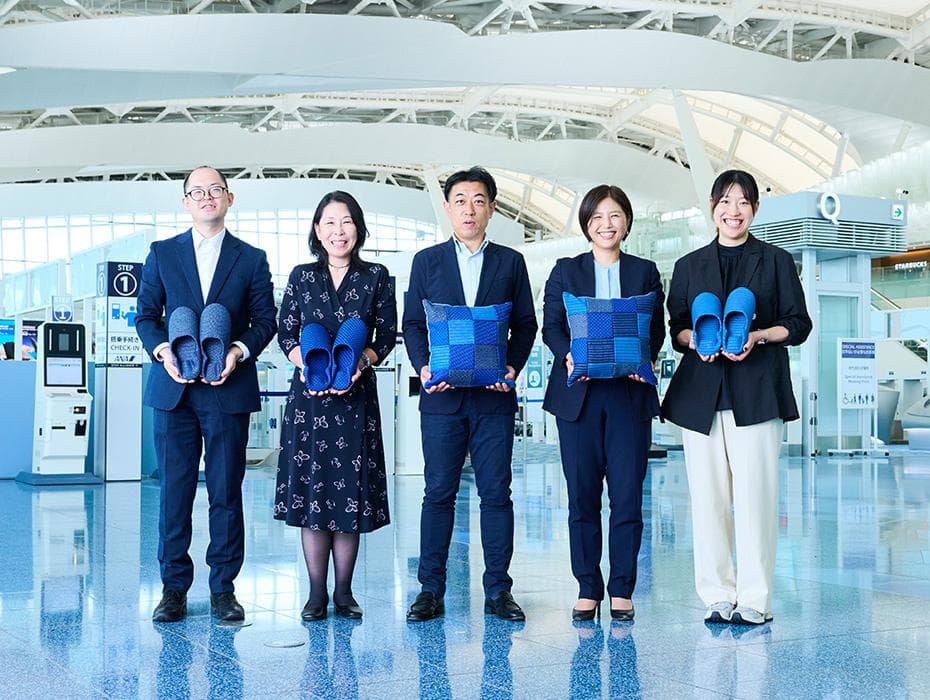

We spoke with Mr. Yahata from ANA Wing Fellows Vie Oji Co., Ltd. (hereafter "AWO")

(3 from AWO on the left, 2 from Onward on the right)

Q. Could you tell us about the challenges you faced in producing the second upcycled product?

Our goal was to reuse small offcuts left after cutting fabric for room shoes, so it was a challenge to decide what items we could make from them. (At first, 11-cm square coasters were among our options.)

Then, we came up with the idea of sewing the pieces together using a patchwork technique. We had consultations with Onward, and the patchwork cushion was born.

Q. What points did you particularly focus on?

The patterns and quantities of the seat covers to be discarded (those to be sent to the room shoe factory) were unpredictable. Furthermore, as the pieces of fabric available to us were offcuts from room shoe production, we were not sure how many 11-cm squares of each pattern could be secured.

At the factory, Goto Co., Ltd., cooperated by carefully cutting out 11-cm squares one by one from the offcuts and counting them.

Based on the number of pieces by pattern, we considered several layout designs that would minimize waste while looking good, and finally decided on these two patterns.

We also refined the details, such as the orientation—vertical, horizontal, or other directions—of each pattern in relation to the overall balance with other patterns, and completed the design.

Also, we upcycled not only the seat cover offcuts from room shoe production but also curtains from airplane galleys, coordinating with related departments to incorporate them into the cushion.

Q. How do you envision the future development of this project?

Going forward, we will continue to further develop this project as we move toward achieving our shared goal of sustainability by bringing together ANA's experience in air travel and Onward's design expertise.

This cushion has been available at the ANA Waku Waku Shop on the ANA Mall website since Monday, August 4.

- * This product is available in limited quantities, and sales will end once stocks are sold out.

The ANA Group will continue striving to reduce waste and make effective use of resources, working hand in hand with its customers.