The main contributing factors to air pollution through the ANA Group’s operations are (1) exhaust emissions from aircraft and (2) exhaust emissions from ground vehicles. Regarding aircraft exhaust emissions, Annex 16 of the Convention on International Civil Aviation of the ICAO has established emission standards for NOx (nitrogen oxides), HC (hydrocarbons), CO (carbon monoxide) and SN (smoke number, or density) in terms of mass of emissions per unit of engine thrust for the ICAO Landing/ Takeoff (LTO) cycle. Appendix III of the Enforcement Regulation of Japan’s Civil Aeronautics Act also contains the same standards, entitled “Emission Standards for Aircraft Operations.”

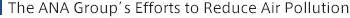

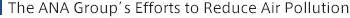

ICAO Landing/Takeoff Cycle

Emission levels are measured during the LTO cycle, which is defi ned as a descent from 3,000 feet to the ground and an ascent to 3,000 feet after takeoff. Engine tests are subject to the thrust settings and times in the chart below.

ANA’s most effective measure to reduce hazardous exhaust emissions from aircraft has been to deploy the latest, most advanced aircraft equipped with state-of-the-art engines. Emissions of aircraft currently in use at the ANA Group are all within ICAO emission standards stipulated in Annex 16.

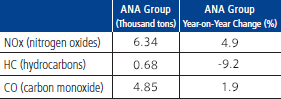

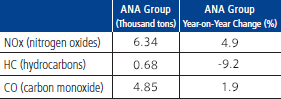

Engine Exhaust Emissions (Fiscal Year Ended March 2012

In the fiscal year ended March 2011, the ANA Group performed four fuel dumpings for unscheduled landings due to equipment failure.)

Quantity and Frequency of Fuel Dumping

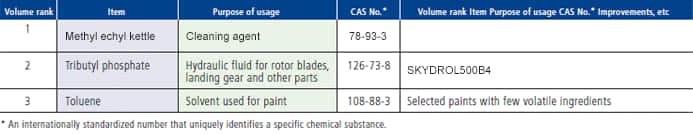

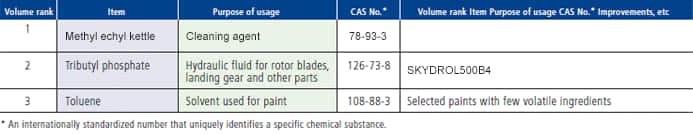

To manage and conduct the required registration of PRTR substances, the ANA Group has created a unified intercompany database that groups these substances according to type, quantity, composition, and usage status. ANA has also worked to strengthen links across the organization in order to centralize all related information at Group companies. From the registration for the fiscalyear ended March 2012, the ANA Group’s total number of PRTR substances increased by 21, and total consumption

* was 24,180 kg. Going forward, the ANA Group will continue to make improvements by conducting operations that give due consideration to any potentially negative environmental impact, and continue to study alternative materials and methods that do not use any designated hazardous substances.

* Total of discharge and disposal

Major Type 1 Designated Chemical Substances Used by the ANA Group (Fiscal Year Ended March 2011)

At Haneda and Narita airports, ANA washes its aircraft at night. In the fiscal year ended March 2012, the ANA Group’s frequency of aircraft washing was virtually unchanged from the previous fiscal year, and improvements in washing procedures helped to reduce both total water usage and water usage per plane. After each washing, water is treated at the airport’s treatment facility and then discharged into the public sewerage system.

ANA Group Water Usage and Frequency of Aircraft Washing

For safety reasons, aircraft are not permitted to take off with snow or ice on the wings, control surfaces, or fuselage. Before departure, snow is removed using hot water or blown off with compressed air (in the case of dry snow), followed by the application of an anti-freezing fluid. The ANA Group fully switched to propylene glycol (not subject to PRTR Law) as of 1996. Moreover, in the winter of 2009-2010 we began using Kilfrost Group PLC’s environmentally friendly de/anti-icing fluid DF Sustain™ at certain airports as an additional environmental measure. Made from bio-glycol rather than petrochemical propylene glycol, this de/anti-icing fluid emits no CO2 during use, and has such superior environmental features as significantly lower toxicity on aquatic fauna than conventional products. It has outperformed conventional de-icing fluids and shown good results. The ANA Group will continue making efforts to develop environmentally friendly de-icing fluids.

Volume and Frequency of Use of Anti-Freezing

and De-Icing Fluids for Domestic and International Flights

As a groundwater and soil pollution countermeasure, in March 2009 the ANA Group adopted a neutral non-methylene chloride paint remover in its fuselage paint removing operations at maintenance centers in Japan. We have also adopted the use of this product at some overseas maintenance centers and plan to progressively expand its use. Moreover, in March 2010 we completed the final prototype of a chrome-free low-VOC (volatile organic compound) intermediate primer that we had been developing with a paint manufacturer since March 2005, and began trial painting on some aircraft. The primer has been favorably evaluated, and we are continuing our efforts to expand and evaluate its trial use toward eventual adoption. Additionally, in the fiscal year ended March 2003 we introduced low-VOC (volatile organic compound) exterior paint, which emits very little volatile gas, and have expanded its use to all ANA Group aircraft.

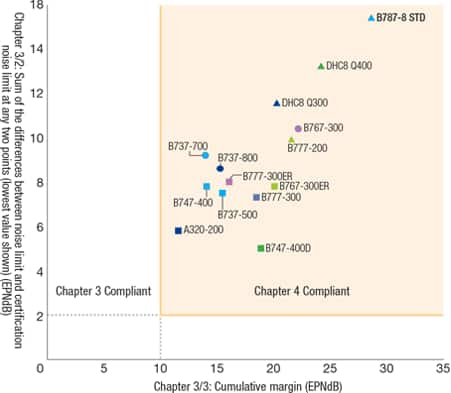

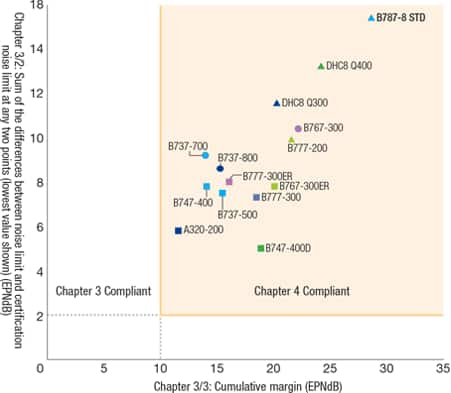

In response to growing demand to reduce aircraft noise in recent years, the ANA Group is working to reduce noise for both people on the ground and aircraft passengers through ongoing efforts to improve flight procedures and aircraft materials. All of the ANA Group’s aircraft conform to Chapter 4, the strictest of the ICAO noise standards. The diagram below shows the margins of each type of aircraft with respect to the noise standards, with positions farther toward the upper right representing quieter aircraft. In the Boeing 787, which we introduced in 2011, a chevron nozzle and new materials help to significantly reduce noise compared with other aircraft.

ICAO Annex 16, Chapter 4 Standards (ANA Group Fleet)

The ANA Group has devised various flight procedures to reduce the impact of flight noise at ground level.

Primary Noise Abatement Procedures Implemented by ANA

Based on participation in programs to verify the effectiveness of noise dampening technologies, and test flights using a Boeing 777-300ER, the ANA Group is modifying noise sources (airframes and engines) and working to improve aircraft performance.

Pictured below are examples of noise abatement measures that are being implemented or investigated.