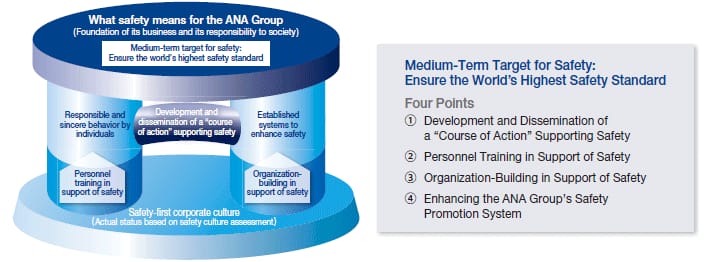

The ANA Group carries out diverse, industry-leading safety promotion activities such as the airline industry’s first internal safety culture evaluation initiative. From the fiscal year ended March 2011, we have further heightened our initiatives to set “Ensure the World’s Highest Safety Standard” as our medium-term target for safety. Our aim is to further strengthen our foundation of safety-first corporate culture and to achieve goals through initiatives built on the two pillars of “Personnel Training in Support of Safety” and “Organization-Building in Support of Safety.”

To achieve our medium-term target for safety, “Ensure the World’s Highest Safety Standard,” we have formulated a medium-term plan to promote safety. In light of factors in our operating environment during the fiscal year ended March 2012 such as the expansion of international routes, the introduction of a new aircraft model, the expansion of alliances, and the merger of ANA and Air Nippon, we formulated the ANA Group Safety Promotion Plan, and focused on personnel training to disseminate the Course of ANA Group Safety Action and organization-building to promote improvement in employee skills.

To further heighten awareness of safety as our top priority, we have undertaken a variety of activities that included distributing cards listing our Safety Principles and Course of ANA Group Safety Action, creating and internally distributing booklets with case studies of accidents, creating safety education materials introducing case studies via video, promoting public awareness via our “Safety Caravan,” and holding safety events during Aviation Safety Promotion Month. Moreover, we surveyed the safety awareness of Group employees in the third biennial Safety Culture Evaluation with questionnaires to measure the effects of our awareness activities. We analyze the relationship with the results of our Employee Satisfaction Survey, and use the information in personnel training. In addition, we use the ANA Safety Education Center (ASEC) to expand opportunities for all Group employees to consider what they can do on behalf of aviation safety and to implement it in their daily work.

To reduce “near-miss” incidents, we have set up a mechanism for active and voluntary reporting when they occur. Our expert assessors evaluate and analyze reported incidents to plan measures to prevent recurrence. Moreover, through external audits by administrative authorities and the International Air Transport Association (IATA) and internal Group safety audits, we identify points for improvement from perspectives inside and outside the organization. In the fiscal year ended March 2012, we reviewed our training curriculum to improve the skills of assessors and internal auditors, taking measures such as introducing regular information exchange meetings. As we work to ensure the world’s highest safety standard, we will continue observing the systems of foreign airlines and surveying and studying advanced initiatives for use in building new organizations in the ANA Group.

To reduce “near-miss” incidents, we have set up a mechanism for active and voluntary reporting when they occur. Our expert assessors evaluate and analyze reported incidents to plan measures to prevent recurrence. Moreover, through external audits by administrative authorities and the International Air Transport Association (IATA) and internal Group safety audits, we identify points for improvement from perspectives inside and outside the organization. In the fiscal year ended March 2012, we reviewed our training curriculum to improve the skills of assessors and internal auditors, taking measures such as introducing regular information exchange meetings. As we work to ensure the world’s highest safety standard, we will continue observing the systems of foreign airlines and surveying and studying advanced initiatives for use in building new organizations in the ANA Group.

In ensuring safety during flights, much is entrusted to the skill of pilots. During the fiscal year ended March 2012, while conducting stricter management of pilot qualifications, training status, health status and other factors, the entire Group took initiatives to improve its safety management structure. For example, we performed detailed analysis of incident probability based on sources including captain’s reports, and used this information to improve education and training for pilots. In addition, by developing training methods that bring pilot training closer to actual operations and enhancing support systems for pilot skill management, we worked to improve everyday safety and operational quality.

In ensuring safety during flights, much is entrusted to the skill of pilots. During the fiscal year ended March 2012, while conducting stricter management of pilot qualifications, training status, health status and other factors, the entire Group took initiatives to improve its safety management structure. For example, we performed detailed analysis of incident probability based on sources including captain’s reports, and used this information to improve education and training for pilots. In addition, by developing training methods that bring pilot training closer to actual operations and enhancing support systems for pilot skill management, we worked to improve everyday safety and operational quality.

We held meetings for employees to exchange ideas about possible incidents during airport operations as we focused on activities to ensure that the Course of ANA Group Safety Action spreads and takes root, and to raise safety awareness among all parties. By systematizing accident prevention activities and rolling out initiatives at all our domestic airports since the fiscal year ended March 2010, the number of prevented incidents reported has risen year by year. By getting employees to keenly sense the possibility of accidents and to report on them, we share potentially unsafe events throughout the organization. We aim for operational safety through the everyday awareness of all employees of potentially unsafe events.

We held meetings for employees to exchange ideas about possible incidents during airport operations as we focused on activities to ensure that the Course of ANA Group Safety Action spreads and takes root, and to raise safety awareness among all parties. By systematizing accident prevention activities and rolling out initiatives at all our domestic airports since the fiscal year ended March 2010, the number of prevented incidents reported has risen year by year. By getting employees to keenly sense the possibility of accidents and to report on them, we share potentially unsafe events throughout the organization. We aim for operational safety through the everyday awareness of all employees of potentially unsafe events.

The primary duty of Inflight Services is to secure the safety of passengers. In the fiscal year ended March 2012, the department strengthened voluntary reporting of near-miss incidents on flights. Based on an analysis of submitted reports, it set safety themes for specific periods and shared countermeasures with cabin crew while conducting reviews of work procedures. The department also regularly promotes safety awareness through direct interaction with the Senior Vice President of Inflight Services and other parties, and through discussions in meetings. Inflight Services introduced electronic tablets in March 2012 to further enhance education for cabin crew, and raised the frequency and quality of education.

The primary duty of Inflight Services is to secure the safety of passengers. In the fiscal year ended March 2012, the department strengthened voluntary reporting of near-miss incidents on flights. Based on an analysis of submitted reports, it set safety themes for specific periods and shared countermeasures with cabin crew while conducting reviews of work procedures. The department also regularly promotes safety awareness through direct interaction with the Senior Vice President of Inflight Services and other parties, and through discussions in meetings. Inflight Services introduced electronic tablets in March 2012 to further enhance education for cabin crew, and raised the frequency and quality of education.

In the fiscal year ended March 2012, groupwide maintenance departments worked to train personnel and build an organization to improve safety and quality. For personnel training, we established and reviewed education programs of all types, and nurtured key persons to support quality. For organization-building, we worked to strengthen measures to prevent incidents by implementing inspections at each workplace based on workplace monitoring by on-site managers and on information regarding near-miss incidents. In addition, aside from on-site work, we have also introduced self-checklists for management tasks in maintenance work, and a system of audits by third-party organizations. Moreover, to strengthen disaster prevention activities, we began experimental safety training. The training, which raises awareness of workplace safety through mock experiences of latent workplace dangers, is expected to have substantial results as a new method of safety training.

In the fiscal year ended March 2012, groupwide maintenance departments worked to train personnel and build an organization to improve safety and quality. For personnel training, we established and reviewed education programs of all types, and nurtured key persons to support quality. For organization-building, we worked to strengthen measures to prevent incidents by implementing inspections at each workplace based on workplace monitoring by on-site managers and on information regarding near-miss incidents. In addition, aside from on-site work, we have also introduced self-checklists for management tasks in maintenance work, and a system of audits by third-party organizations. Moreover, to strengthen disaster prevention activities, we began experimental safety training. The training, which raises awareness of workplace safety through mock experiences of latent workplace dangers, is expected to have substantial results as a new method of safety training.