Efforts to Reduce CO2 Emissions

Aircraft

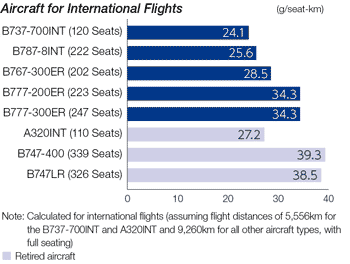

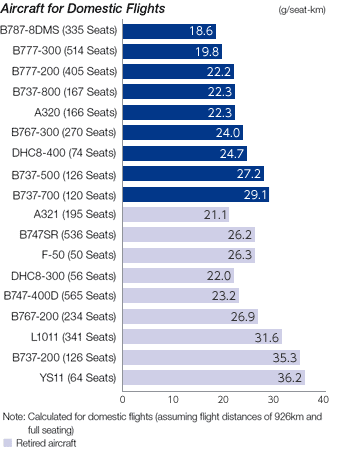

Introducing New Environmentally Friendly Aircraft

The most effective method of reducing fuel consumption and CO2 emissions is to introduce new types of aircraft which offer greater fuel efficiency. For example, the ANA Group was the launch customer for the Boeing 787, an aircraft which features engines that incorporate the latest technologies, a more aerodynamically efficient wing, and a lightweight structure which makes extensive use of composite materials. Furthermore, the Group was the first to order the Mitsubishi Regional Jet (MRJ) manufactured by Mitsubishi Aircraft Corporation, and has plans to introduce 25 of these aircraft. With an eye on the next 15 years, the ANA Group also placed an order for 70 new aircraft including Boeing 787-9, Boeing 777-9X, Airbus A320neo and Airbus A321ceo in March 2014 to ensure a steady replacement of the latest aircraft.

<Fuel Consumption by Aircraft Type>

Fuel Efficiency Project

We have worked to increase fuel efficiency through a project undertaken since 2008. However, we have been influenced by persistently high crude oil prices, increased fuel-related costs due to the yen's depreciation, and an increase in total CO2 emissions due to the expansion of international services. Under the circumstances, since April 2014, we have revamped the framework under the key themes of unified group-wide implementation and visualization.

We will extensively work to achieve the project's objectives by proposing and sharing a variety of ideas to lead to results.

Examples of Initiatives in the Fuel Efficiency Project

In the Air

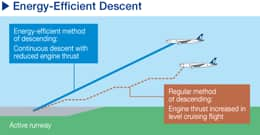

Promoting an Energy-Efficient Descent Method

Continuous Descent Approach (CDA) is a method in which an aircraft descends continuously with minimum engine thrust from the start of descent until the final approach point, as opposed to descending in stages with periods of level flight. This method is effective for reducing both CO2 emissions and noise. The ANA Group began implementing this method for late-night and early-morning flights at Kansai International Airport and is expanding its use to other applicable airports while cooperating with the relevant organizations.

Reducing Thrust Reverser Usage and Single-Engine Taxiing

While ensuring safety, the ANA Group is reducing the use of thrust reversers during landing as a means to reduce engine output, which in turn reduces both CO2 emissions and noise. CO2 emissions are further reduced through the use of single-engine taxiing after landing. The decisions to implement these measures are made by the aircraft captains and are based on a range of factors, including airport, weather, runway, and aircraft conditions as well as instructions from the control tower.

Engine Washing

When an engine is operating, fine dust collects on the compressor and this decreases fuel efficiency. The ANA Group regularly washes engine compressors to clear away this dust and restore performance, improve fuel efficiency, and reduce CO2 emissions.

Equipping Aircraft with Winglets

Winglets are a type of wingtip devices fitted to the end of the main wings. Attaching winglets reduces air resistance that occurs during flight. The use of winglets on the Boeing 767-300ER, which is operated on long-haul flights, can improve fuel efficiency by around 5% and reduce per-aircraft CO2 emissions by 2,100 tons per year. In 2010, the ANA Group became the first domestic airline to attach winglets to a Boeing 767-300ER and has since then consecutively added wingtips to its Boeing B767-300ER fleet.

Introduction of Next-generation Paint System

We are employing a next-generation paint system that offers superior weather resistance in contrast with traditional coating, contains few volatile organic compounds, and which results in lighter aircraft.

Reducing the Amount of Water on Board

A lighter aircraft will consume less fuel and thereby emit less CO2. As part of its efforts to reduce aircraft weight, the ANA Group has been reviewing the amount of drinking water that is carried by aircraft on both international and domestic routes. When an aircraft arrives at Haneda Airport, any water remaining onboard is recycled for purposes such as facility cleaning.

Reducing the Weight of Cabin Seats

The ANA Group developed new standard seats for domestic routes in partnership with Toyota Boshoku Corporation.

By combining the ANA Group's know-how as an airline with Toyota Boshoku's manufacturing technologies cultivated over many years through the development of automobile seats, we developed comfortable seating that meets our technical specifications as well as our desire to provide a relaxing environment for all based on our policy of assuring our passengers a “memorable journey.”

In developing these seats, we managed to reduce the overall cabin weight by 195 kilograms per aircraft compared to conventional seating without compromising comfort. This weight reduction has, in turn, allowed us to cut our annual fuel consumption by approximately 15 kiloliters per aircraft.

Reducing the Weight of Onboard Items

In order to achieve greater fuel efficiency, the ANA Group is working to reduce not only the weight of the aircraft itself, but also that of the equipment and items which are carried on board. Reducing the weight of both the WINGSPAN inflight magazine and Sky Shop inflight sales catalog by changing the type of paper they are printed on and reducing the number of pages are examples of these detailed efforts. Another example is the adjustment of the amount of utensils, beverages, etc., that are loaded and the removal of low-demand items based on reports from cabin attendants. By replacing paper manuals with digital versions, the weight of cabin attendant manuals was also reduced by 70%.