Measures for Air Pollution, Chemical Substances, and Noise

Air Pollution Measures

The ANA Group’s Efforts to Reduce Air Pollution

The ANA Group's operations contribute to air pollution mainly through emissions from aircraft and emissions from ground vehicles. Annex 16 of the ICAO's Convention on International Civil Aviation regulates emission standards for NOx (nitrogen oxides), HC (hydrocarbons), CO (carbon monoxide), and SN (smoke number, i.e., density) in terms of mass of emissions per unit of engine thrust during an ICAO Landing/Takeoff (LTO) cycle. Appendix III of Japan's Ordinance for Enforcement of the Civil Aeronautics Act also contains the same standards, which are identified as “Emission Standards for Aircraft Engines.

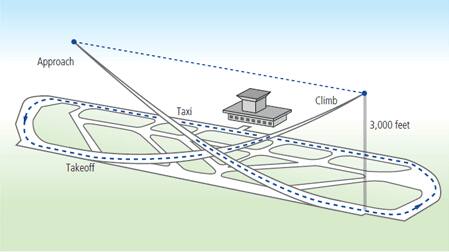

ICAO Landing/Takeoff (LTO) Cycle

Emission levels are measured during the LTO cycle, which is defined as a descent from 3,000 feet to landing and a climb to 3,000 feet after takeoff. Engine tests are subject to the thrust settings and durations in the chart below.

| Thrust setting | Rated output (%) | Time in mode (min.) |

|---|---|---|

| Takeoff | 100 | 0.7 |

| Climb | 85 | 2.2 |

| Approach | 30 | 4.0 |

| Taxi/Idle | 7 | 26.0 |

Low-Emission Aircraft

The ANA Group has introduced the latest aircraft equipped with state-of-the-art engines as it is the most effective means to reduce hazardous emissions. All engines that power aircraft currently operated by the ANA Group comply with the emission standards stipulated in Annex 16 of the ICAO's Convention on International Civil Aviation.

Engine Emissions (FY2014)

| ANA Group (Ten Thousand tons) |

ANA Group Year-on-Year Change(%) |

|

|---|---|---|

| NOx(nitrogen oxides) | 0.74 | -2.6 |

| HC(hydrocarbons) | 0.05 | -16.7 |

| CO(carbon monoxide) | 0.44 | -4.3 |

Fuel Dumping

Equipment malfunctions or passengers requiring immediate medical care often necessitate unscheduled landings. In such circumstances, if the aircraft's weight exceeds its maximum landing weight, the aircraft must dump fuel to reduce its weight to ensure a safe landing. Fuel dumping is performed only when necessary. Different airports designate specific dumping locations and altitudes. For example, fuel dumping operations are performed over oceans to avoid affecting urban areas. When dumped at high altitude, fuel diffuses into a mist that has minimal impact at ground level. During the 2014 fiscal year, the ANA Group experienced three cases that involved fuel dumping, and approximately 144 kiloliters of fuel was dumped off the eastern coast of Japan and the southern sea of New York.

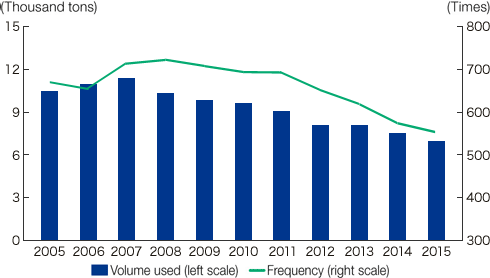

Quantity and Frequency of Fuel Dumping

Reducing Use of Chemical Substances

Compliance with Japan's Pollutant Release and Transfer Register (PRTR) Law

To manage and perform the required registration of chemical substances, the ANA Group has created a unified intercompany database that includes detailed information regarding the type, quantity, composition, and usage status of these substances. The ANA Group has also worked to strengthen coordination across the organization so that all related information at Group companies can be aggregated in the database. The amount of such substances that was released or transferred during the 2014 fiscal year was 18,575kg.

Use of dichloromethane paint remover was on par with the previous fiscal year as a result of the ANA Group's adoption of non-methylene chloride-based paint remover. The Group will continue to make improvements by conducting operations that give due consideration to their environmental impact and studying alternative materials and methods that do not use any designated hazardous substances.

Designated Chemical Substances Used by the ANA Group (FY2014)

| Volume rank | Item | Purpose of usage | CAS No.* | Volume rank Item Purpose of usage CAS No.* Improvements, etc. |

|---|---|---|---|---|

| 1 | Tri-n-butyl phosphate | Hydraulic oil for control surfaces, landing gear, etc. | 126-73-8 | SKYDROL500B4/ SKYDROL LD4 |

| 2 | Toluene | Solvent used for paint | 108-88-3 | Selected paints with few volatile ingredients |

| 3 | Xylene | Plating | 1330-20-7 | |

| 4 | Hexavalent chromium | Sealant | - |

* An internationally standardized number that uniquely identifies a specific chemical substance.

Aircraft Washing and Discharged Water Processing

The ANA Group's aircrafts are washed during nighttime hours at both Haneda and Narita airports. The Group has determined the optimal interval between washes in order to reduce water usage while still maintaining the appearance of the aircraft. Both the number of washes and the amount of water used during the 2014 fiscal year were reduced on a year-on-year basis. After each washing, the used water is properly treated at the airport's treatment facility.

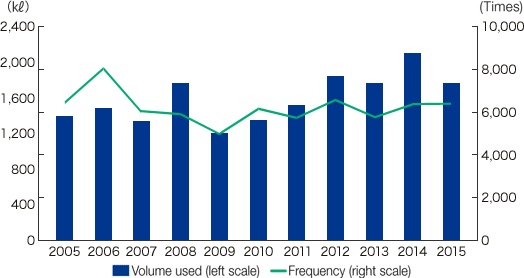

ANA Group Water Usage and Aircraft Washing Frequency

Environmental Measures for Anti-Icing Fluid

For safety reasons, aircraft are not permitted to take off with snow or ice on their wings, control surfaces, or fuselage. Before departure, snow is removed using hot water or blown off with compressed air (in the case of dry snow), and this is followed by the application of an anti-icing fluid. Since 1996, the ANA Group has been using only propylene glycol (a non-PRTR substance) for this purpose.

Although the Group made efforts to improve operations and reduce the use of anti-icing agents this year, heavy snowfall in the Hokkaido and Tohoku regions during the 2013-2014 winter season coupled with severe snowstorms at both Haneda and Narita airports in February led to increased usage.

Volume and Usage Frequency of Anti-Icing Fluids for Domestic and International Flights

Reducing PRTR Substance Usage and Volatile Gas Emissions during Aircraft Painting

In March 2009, the ANA Group adopted a neutral non-methylene chloride paint remover for fuselage paint removal operations at maintenance centers in Japan as a groundwater and soil pollution prevention measure. This type of paint remover is also being used at aircraft maintenance hangars outside Japan. Furthermore, the Group has been working with paint manufacturers since the 2004 fiscal year to develop a low-VOC (volatile organic compound), chrome-free primer. Following trials, this primer is now being used for the Group's Airbus and Bombardier aircraft. Since the 2002 fiscal year, the Group has also been using a low-VOC paint to paint the exteriors of all of its aircraft.

Noise Abatement Measures

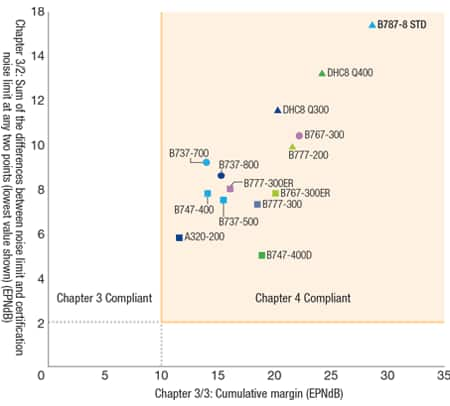

In response to growing concerns regarding noise pollution from aircraft in recent years, the ANA Group has been working to reduce noise for people on the ground as well as aircraft passengers through continued efforts to improve both aircraft features and flight procedures. All of the ANA Group's aircraft comply with Chapter 4 of Annex 16 in the Convention on International Civil Aviation, which are the ICAO's strictest standards regarding aircraft noise. The diagram below shows the margins of each type of aircraft that the ANA Group operates with respect to compliance with ICAO noise standards, with positions farther toward the upper right representing quieter aircraft. The Boeing 787, which the ANA Group began introducing in 2011, features the latest structural materials and engine nozzle chevrons and clearly produces a significantly lower amount of noise compared to other types of aircraft.

ICAO Annex 16, Chapter 4 Standards(ANA Group Fleet)

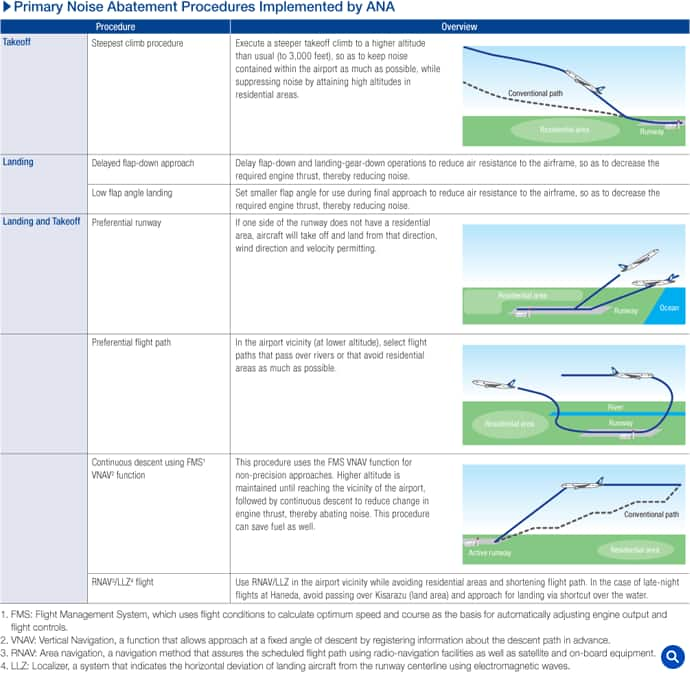

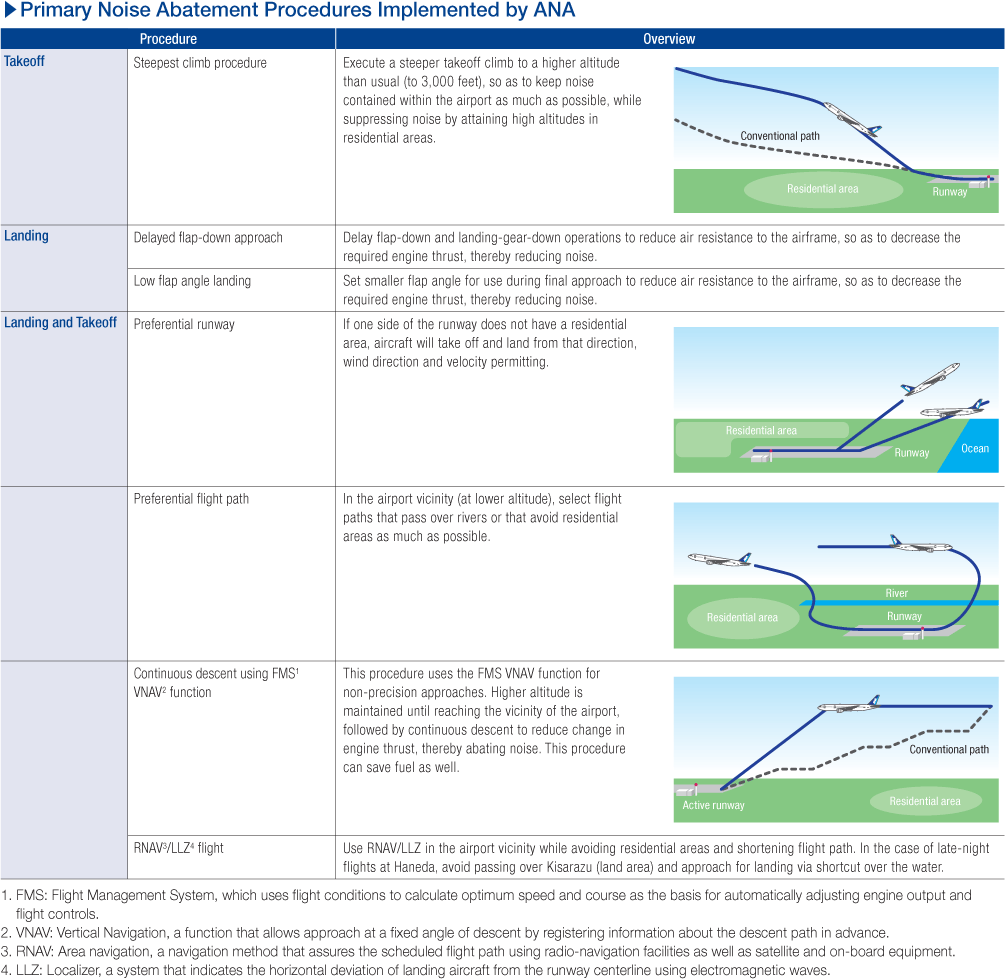

Improving Flight Procedures

The ANA Group has adopted various flight procedures to reduce the impact of flight noise at ground level.

Improving Aircraft Features

The Boeing 787 produces significantly less noise than previous commercial aircraft, and this is due in no small part to the engine and nacelle improvements listed in the table below. The ANA Group participated in the Quiet Technology Demonstration (QTD) 2 program with several key industry partners including Boeing, Goodrich, GE Aircraft Engines and NASA in 2005 which involved test flights with ANA Boeing 777-300ER aircraft. It can be said that the aforementioned improvements to the sources of aircraft noise (airframe and engines) were the result of this program. Examples of noise reduction features that have been implemented are shown below.